The new standard in universal turning – DMG MORI CLX 450 TC

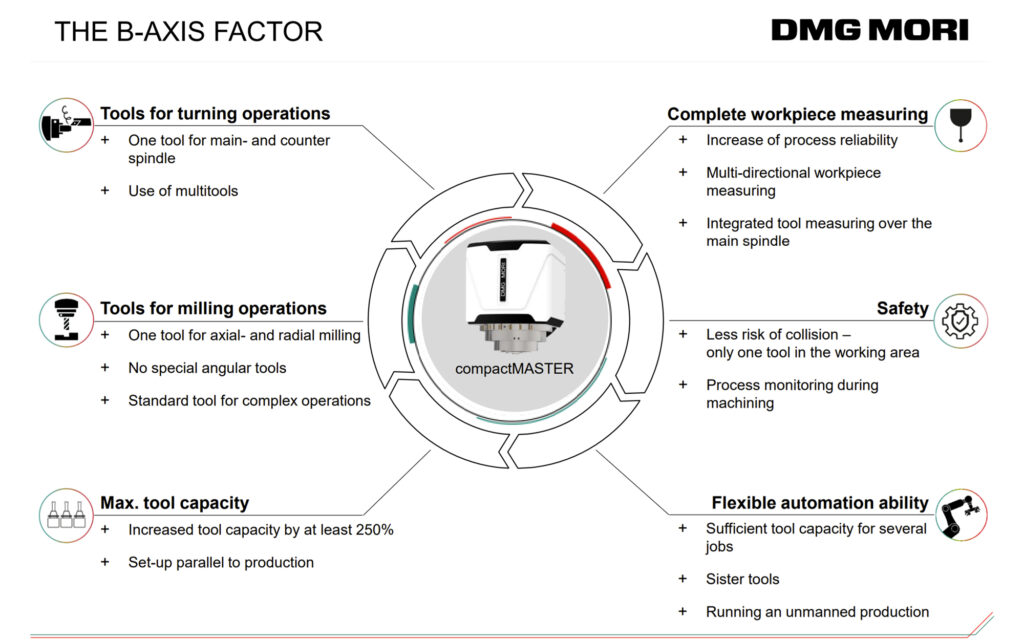

When market demands change, then DMG MORI develops a brand new defined universal turning machine. DMG MORI CLX 450 TC main feature is B-AXIS factor which requires numerous advantages such as tools for turning and milling operations, increased tool capacity, complete workspace measuring, flexible automation ability and of course improved safety. Let’s take a closer look.

Next to B-AXIS there are many more highlights. One of them is tool handling that provides high tool capacity up to 60 tools and fast chip-to-chip times of under 7 seconds. Also, CLX 450 TC has a huge working area which makes operation possibilities way more flexible thanks to 1,100 mm turning length and 400 mm turning diameter. Another new feature is cutting performances thanks to main and counter spindle as integrated spindle motors with 5.000 rpm and 345 Nm for max.

The added value to every universal turning machine:

✓ Tool magazine with 30 or 60 tools for highest flexibility

✓ Minimal set-up and idle times thanks to multitools and sister tools

✓ Eccentric turning and milling with the Y-axis as standard

✓ No angular tools needed thanks to interpolation of the B-Axis (0,001° resolution)

✓ Maximum usability of the working area with compactMASTER spindle

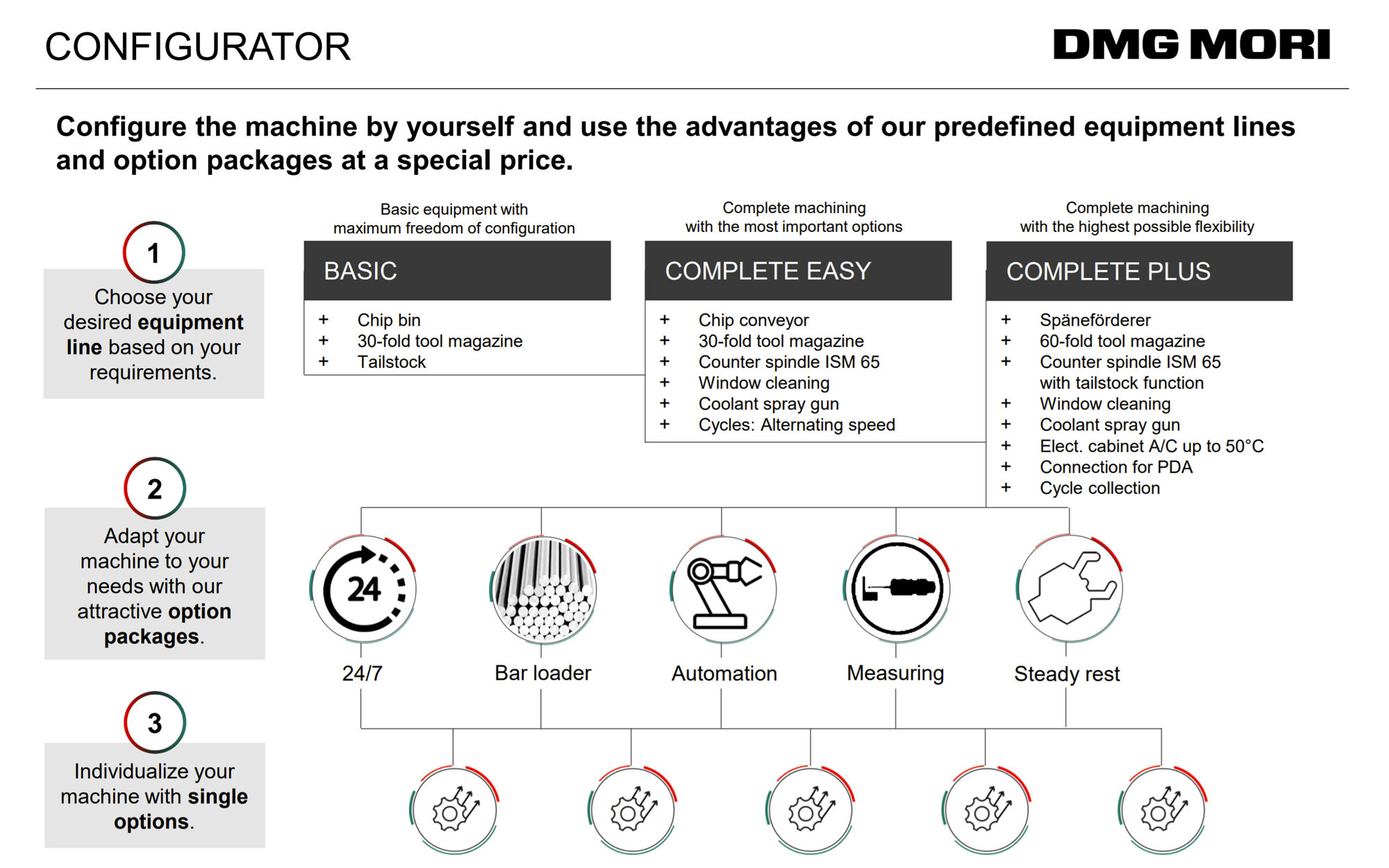

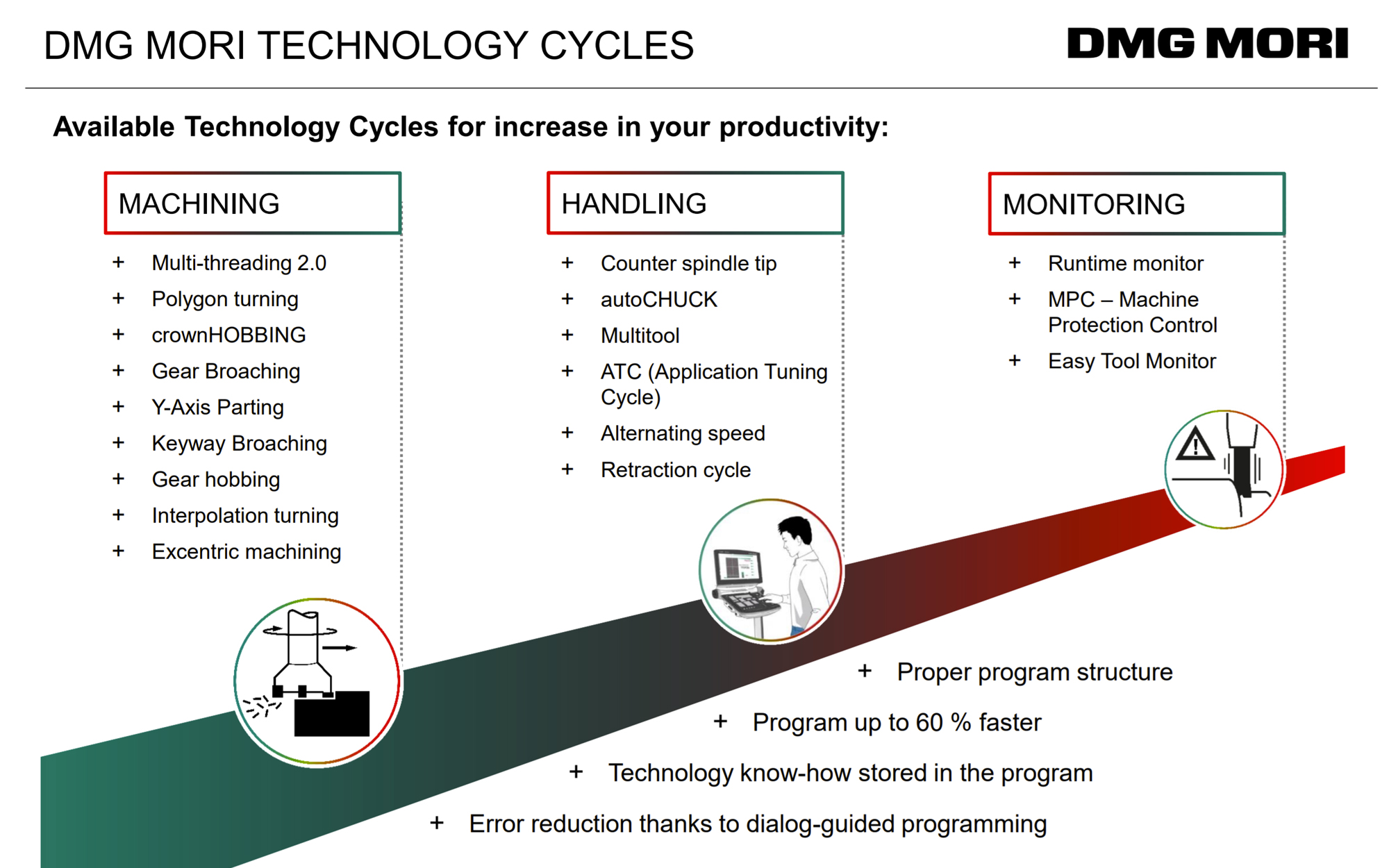

However, CLX 450 TC is customizable as well. For example Technology Cycles option which dialog-guided programming of complex operations increases your productivity and Tool Measuring option that allows measuring of fixed and rotating tools outside of the working area protected against chips. New CLX 45o TC meet your needs: